Laser Alignment

Laser Alignment

Nearly 50% of machine failures are due to misalignment. Indications of misalignment in rotating machinery are shaft wobbling, excessive vibration (in radial and axial directions), excessive bearing temperature (even if adequate lubrication is present), noise, bearing wear, and coupling wear. Misalignment can be especially detrimental to rolling-element bearing life.

Machines which are precision aligned will function for a longer period and costs less to run. Common misalignments are the result of two rotating shafts not parallel to one another, either by a slightly offset or angled gap at the coupling. However, many times it is both, which is called a compound misalignment.

There are several causes for misalignment including:

-

Pipe strain

-

Thermal expansion

-

Human error

-

Wear causing sheave to deform

-

Baseplate settles irregular to form a soft foot

-

Inaccurate assembly of components, such as motors and pumps

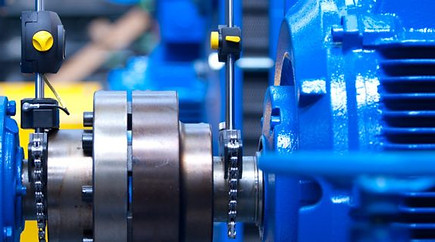

The primary point to remember is that any unsteady motion or movement to shaft center lines that goes against the intended motion of the machine can cause bearing or couplings to be stressed and the seals to fail. In addition to shaft alignment, we also offer belt and chain alignment.